Cutting Fluid Physical Filter Pure Pneumatic Power Low Energy Consumption

Product Details:

| Place of Origin: | China |

| Brand Name: | Diang Tianke |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | WOODEN CASE |

| Delivery Time: | 7-15 workdays |

| Payment Terms: | LC, T/T, PayPal, Western Union, Small-amount payment, Money Gram |

| Supply Ability: | 300 pis/month |

|

Detail Information |

|||

| Model NO.: | Datk-qz | Installation: | Horizontal |

|---|---|---|---|

| Centrifuge Type: | Horizontal Spiral Centrifuge | Distillation Equipment Type: | Steam Distillation Equipment |

| Extraction Tower Type: | Vibration Plate Tower | Pressure: | High Pressure |

| Condition: | New | Weight: | 78kg |

| Processing Capacity: | 8000L | Working Air Pressure: | 0.4-0.6MPa |

| Air Consumption: | 0.6m³/Min Max | Filtration: | 0.75mm |

| Transport Package: | Wooden Case | Specification: | 850*450*900mm |

| Trademark: | Datk | Origin: | China |

| HS Code: | 8401200000 | Warranty: | 1 Year |

| Type: | Automatic | Object: | Cosmetic |

| Separation Mode: | Filter Type | Application: | Metalworking Industry |

| Capacity: | 500 Kg/h | Dimension: | 1200mm X 800mm X 1500mm |

| Frequency: | 50Hz | Material: | Stainless Steel |

| Power: | 3.5 KW | Power Source: | Electric |

| Voltage: | 220V | ||

| Highlight: | Physical Filter Cutting Fluid Physical Filter,Pure Pneumatic Cutting Fluid Physical Filter |

||

Product Description

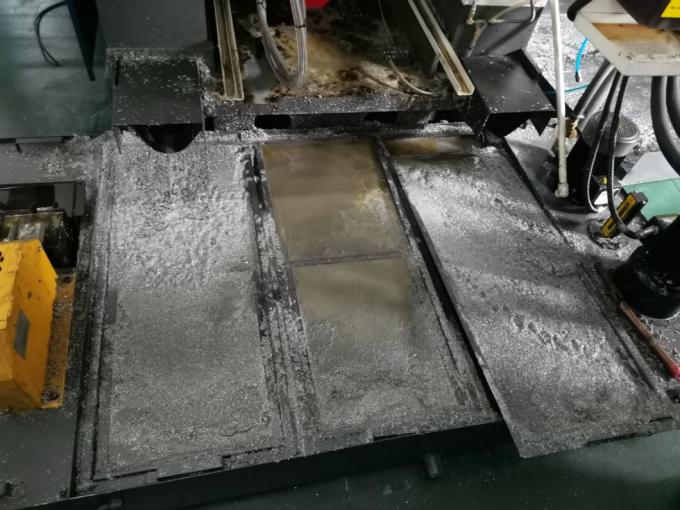

Cutting Fluid Physical Filter Pure Pneumatic Power Low Energy Consumption

Product Introduction

The liquid tank cleaning machine, also known as the machine tool water tank slag remover, is a product independently developed and designed by the company. The filter barrel has a large capacity, and the filtration accuracy can be customized. 24-hour online filtration saves manual cleaning time.

With years of production experience in the industry, the company has a professional sales and technical team to provide you with high-quality products and services!

Equipment parameters

| Product size | 850*450*900mm |

| Equipment weight | 78kg |

| Working air pressure | 0.4-0.6MPa |

| Filtration | 0.75mm |

| Processing capacity | 7000-8000L/h |

Traditional treatment methods for metal debris and oil sludge:

1. There are three drawbacks to using an iron shovel to scoop out sediment after it reaches a certain amount: not cleaning thoroughly, requiring downtime, long processing time, and low work efficiency.

2. Using a filtered hourglass for salvage has low processing efficiency, and the cutting fluid is prone to spillage and splashing onto the skin during the processing, which can easily cause skin allergies. Cutting fluid leakage not only causes waste of cutting fluid, but also exacerbates the dirty, disorderly, and poor phenomena in the workshop.

3. Pouring out the cutting fluid and treating the remaining metal debris and oil sludge separately not only increases the environmental treatment pressure of the cutting fluid, but also increases the cost of cutting fluid treatment for enterprises.

4. Some metal debris at the edges and corners of the water tank cannot be scraped, and if cleaned by hand, it is easy to cause work-related injuries, and the cleaning effect is also average.

The benefits of a cutting fluid slag cleaning and liquid changing machine

1. Timely clean up sediment and oil sludge to reduce damage to equipment;

2. Timely blocking the favorable conditions for bacterial growth and extending the service life of cutting fluid;

3. The slag cleaning and liquid changing machine has high work efficiency, and it only takes 55 seconds to clean the liquid tank of a CNC machining center. It works online, saving time and effort, and does not affect the production progress;

4. High cost-effectiveness, one slag cleaning and liquid changing machine can clean multiple machine tools, imported quality, durable, and consumables free.