Customizable Chip Sludge Removal Machine For CNC Liquid Tank Cleaning

Product Details:

| Place of Origin: | China |

| Brand Name: | Diang Tianke |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | WOODEN CASE |

| Delivery Time: | 7-15 workdays |

| Payment Terms: | LC, T/T, PayPal, Western Union, Small-amount payment, Money Gram |

| Supply Ability: | 300 pis/month |

|

Detail Information |

|||

| Model NO.: | Datk-qz | Installation: | Horizontal |

|---|---|---|---|

| Centrifuge Type: | Horizontal Spiral Centrifuge | Distillation Equipment Type: | Steam Distillation Equipment |

| Extraction Tower Type: | Vibration Plate Tower | Pressure: | High Pressure |

| Condition: | New | Weight: | 78kg |

| Processing Capacity: | 8000L | Working Air Pressure: | 0.4-0.6MPa |

| Air Consumption: | 0.6m³/Min Max | Filtration: | 0.75mm |

| Transport Package: | Wooden Case | Specification: | 850*450*900mm |

| Trademark: | Datk | Origin: | China |

| HS Code: | 8401200000 | Warranty: | 1 Year |

| Type: | Automatic | Object: | Cosmetic |

| Separation Mode: | Filter Type | Application: | Metalworking Industry |

| Capacity: | 500 Kg/h | Dimension: | 1200mm X 800mm X 1500mm |

| Frequency: | 50Hz | Material: | Stainless Steel |

| Power: | 3.5 KW | Power Source: | Electric |

| Voltage: | 220V | ||

| Highlight: | Customizable Chip Sludge Removal Machine,CNC Chip Sludge Removal Machine |

||

Product Description

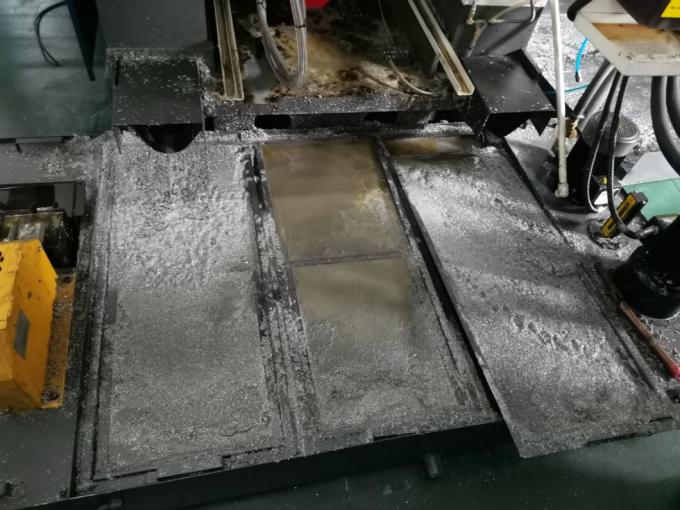

Customizable Chip Sludge Removal Machine for CNC Liquid Tank Cleaning

Product Introduction

The liquid tank cleaning machine, also known as the machine tool water tank slag remover, is a product independently developed and designed by the company. The filter barrel has a large capacity, and the filtration accuracy can be customized. 24-hour online filtration saves manual cleaning time.

With years of production experience in the industry, the company has a professional sales and technical team to provide you with high-quality products and services!

Equipment parameters

Product name: Machine tool slag cleaning machine CNC liquid tank slag cleaning and liquid changing equipment

Usage: Cleaning slag and replacing cutting fluid

Attribute: An environmentally friendly device that can quickly remove metal debris from machine tool sinks and replace cutting fluids

Type: A precision filter with no consumable filter and pressure mode for slag cleaning and liquid exchange

Advantages: 24-hour online rapid slag cleaning, high efficiency, fast speed, simple and convenient operation, product safety and durability

Types of slag removal: various metal debris, non-metallic debris, dust, oil sludge, etc

Applicable object: machining workshop

Model: DATK-QZ006

Product size: 850 * 450 * 900mm

Inlet diameter: 38mm

Water outlet diameter: 45mm

Type: Filter+Pressure

Weight: 78kg

Material: stainless steel 304+sheet metal baking paint

Inlet diameter: 10mm

Working pressure: 0.4-0.6MPa

Filtering accuracy: 0.75mm (customizable)

Air consumption: 0.6m ³/min maximum

Processing capacity: 0-8m ³/h

after-sale service

Starting from the date of product sale, our company provides regular quality tracking and follow-up services for the products purchased by users. We provide answers to problems encountered by users in daily use, solve problems encountered by users in real time during equipment use, communicate and exchange ideas with users on possible small problems that may occur at each stage of the equipment, and prevent equipment failures, detect equipment problems early, and eliminate them in a timely manner to ensure the normal operation of the user's equipment.

Company Introduction

Guangzhou Di'angtianke Automation Co., Ltd. specializes in the research and development, design, manufacturing, and sales of dry suction dual-purpose slag cleaning machines, oil-water separators, cutting fluid slag removal machines, and low-temperature evaporation equipment for waste liquids. The company is committed to providing comprehensive support for cleaning and environmental protection technology solutions, with a professional technical support team and over 10 years of experience in environmental equipment research and development.

Company team: Integrity, initiative, mutual assistance, and enthusiasm for innovation

Company tenet: integrity-based, service-oriented. Satisfy different customer needs and continuously improve customer satisfaction; It is the core of the work of all employees in our company.