CNC Machine Oil Skimmer,Remove floating oil and sterilize

Product Details:

| Place of Origin: | China |

| Brand Name: | Diang Tianke |

| Certification: | ISO9001 |

Payment & Shipping Terms:

| Price: | Negotiable |

|---|---|

| Delivery Time: | 7-15 workdays |

| Payment Terms: | LC, T/T, PayPal, Western Union, Small-amount payment, Money Gram |

|

Detail Information |

|||

| Centrifuge Type: | Disc Centrifuge | Distillation Equipment Type: | Steam Distillation Equipment |

|---|---|---|---|

| Extraction Tower Type: | Vibration Plate Tower | Pressure: | High Pressure |

| Condition: | New | Weight: | 49kg |

| Size: | 650*400*800mm | Voltage: | 220V |

| Power: | 150W | Ozone Value: | 500mg/M3 |

| Processing Capacity: | 1000-3000L/H (Adjustable) | Transport Package: | Wooden Case |

| Specification: | Wooden Box Size750*450*900mm | Trademark: | Datk |

| Origin: | China | After-sales Service: | Life |

| Warranty: | One Year | Type: | Separating Plant |

| Separation Mode: | Filter Type | Operating Type: | Continuous Type |

| Installation: | Vertical | ||

| Highlight: | Sterilize CNC Machine Oil Skimmer |

||

Product Description

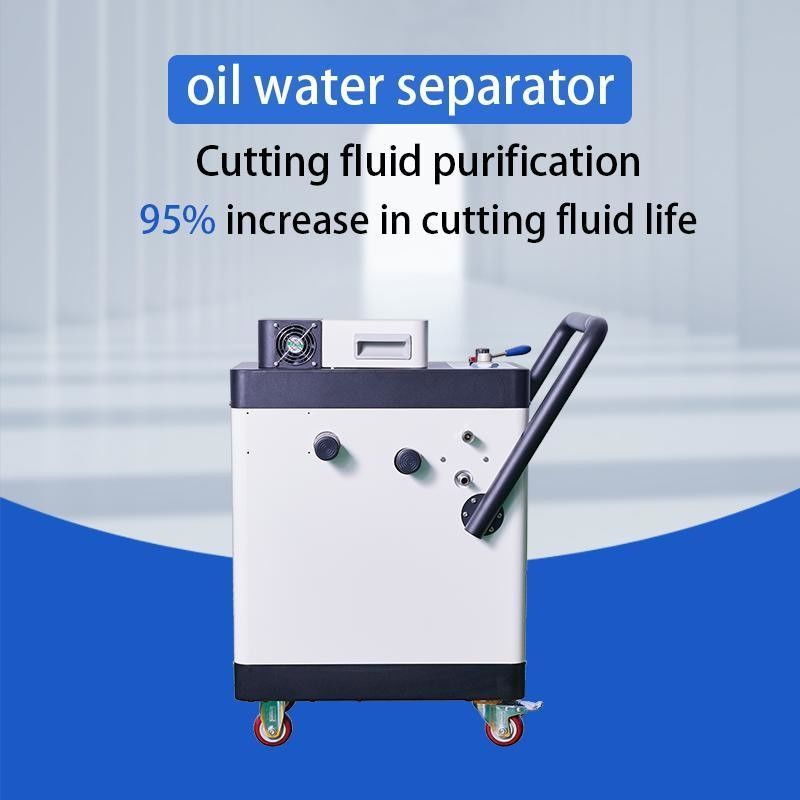

CNC Machine Oil Skimmer,Remove floating oil and sterilize

Product Introduction

The oil-water separator is a cutting fluid oil-water separator that integrates oil removal, impurity removal, and deodorization. Three stage separation, efficient operation of imported skim oil steel strip, visible separation effect, oil-water separation rate up to 98%. The oil-water separator is equipped with a nano aeration sterilization device, which can kill anaerobic bacteria in the cutting fluid and effectively prevent the cutting fluid from smelling and deteriorating. Cutting fluid oil-water separation makes the cutting fluid cleaner and has a longer service life.

Product advantages:

1. Three stage separation, high oil-water separation rate, efficient removal of floating oil on the surface of cutting fluid, with a separation rate of over 98%.

2. Comprehensive deodorization, ozone+nano aeration structure, effectively kills a large number of harmful microorganisms such as anaerobic bacteria that grow in the cutting fluid.

3. 0 consumables, low energy consumption, working for less than 24 hours with less than 2 kWh of electricity.

4. Improve the service life of cutting fluid by 95%, greatly alleviating the environmental pressure of sewage treatment.

5. Unique device protection function, intelligent start stop technology, to avoid long-term overload work.

6. Workpiece cleaning effectively prevents floating oil from adhering to the workpiece, greatly improving the surface cleanliness of the workpiece.

7. Built in patented structure effectively removes powder from cutting fluid.

| Processing capacity | 1000-3000L/H (adjustable) |

| Ozone value | 500mg/m3 |

| Floating oil removal rate | Over 98% |

| Voltage | 220V |

| Power | 150W |

| External dimensions | 620 * 420 * 850mm |

| Applicable object | water-based cutting fluid equipment |

| Weight | :49kg |

| Filtering accuracy: | 0.3mm (customizable) |

| Ozone value: | 100-150mg/H |

| Floating oil removal rate: | 98% or above |

(Before purification)

(Before purification)

(After purification)

(After purification)