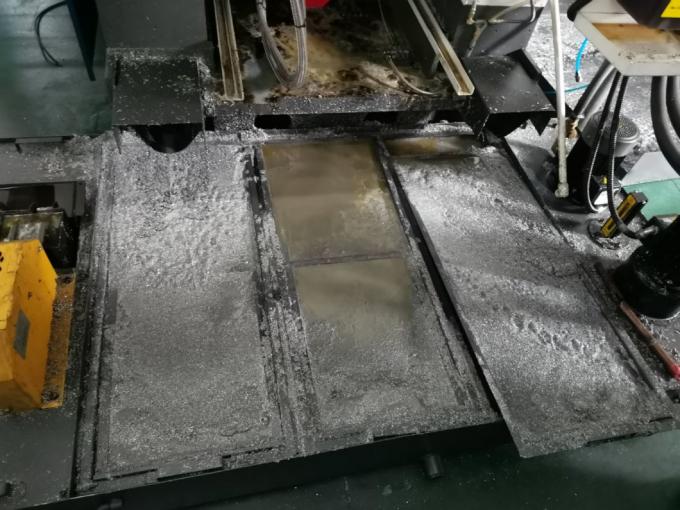

Multi functional CNC slag remover, vacuum cleaner, iron filings suction, slag removal

Product Details:

| Place of Origin: | China |

| Brand Name: | Diang Tianke |

Payment & Shipping Terms:

| Price: | Negotiable |

|---|---|

| Delivery Time: | 7-15 workdays |

| Payment Terms: | LC, T/T, PayPal, Western Union, Small-amount payment, Money Gram |

|

Detail Information |

|||

| Installation: | Not Have | Centrifuge Type: | Not Have |

|---|---|---|---|

| Distillation Equipment Type: | Not Have | Extraction Tower Type: | Not Have |

| Pressure: | High Pressure | Condition: | New |

| Equipment Weight: | 108kg | Working Air Pressure: | 0.2-0.5MPa |

| Working Voltage: | AC220V | Flow: | 8000L/H |

| Transport Package: | Wooden Box | Specification: | 790*530*1000mm |

| Trademark: | Datk | Origin: | China |

| After-sales Service: | Life | Warranty: | One Year |

| Type: | Centrifuge | Object: | Cutting Fluid |

| Separation Mode: | Filter Type | Operating Type: | Continuous Type |

| Highlight: | Multi functional CNC slag remover,Vacuum cleaner CNC slag remover |

||

Product Description

Multi functional CNC slag remover, vacuum cleaner, iron filings suction, slag removal

Company Profile

Equipment parameters

| Product size | 790 * 530 * 1000mm | Packaging wooden box size | 950 * 650 * 1100mm |

| Equipment weight: about | 108kg | Inlet diameter | 38mm |

| Outlet diameter | 45mm | Inlet diameter | 10mm |

| Working pressure | 0.2-0.5Mpa | Working voltage/power | 220V/3kw |

| Filtering accuracy | 0.75mm (customizable) | Wet extraction flow rate | 7000-8000L/H |

| Maximum dry suction force | -0.04MPa |

main features

main features

Simple structure and fast cleaning speed: The liquid tank cleaning machine has a compact design, high cleaning efficiency, and can quickly complete the pumping and cleaning of a large amount of cutting fluid.

Easy to maintain: This device has low maintenance costs and can operate stably for a long time, reducing the maintenance burden on enterprises.

Efficient filtration: Adopting a multi-stage filtration device, it can filter out metal cutting and other impurities in the cutting fluid while pumping, achieving solid-liquid separation.

Multifunctional: It can not only be used for purifying cutting fluids and cleaning oil sludge and debris in storage tanks, but also as a cleaning equipment for liquid fluids such as water and oil splashed out in machining workshops.

Energy saving and environmental protection: By purifying and treating emulsions online, recycled water can be recycled and reused, reducing the total amount of emulsion emissions, lowering enterprise emission costs, and saving freshwater resources.