Extend Cutting Fluid Service Life with Sludge Cleaning Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | Diang Tianke |

Payment & Shipping Terms:

| Price: | Negotiable |

|---|---|

| Delivery Time: | 7-15 workdays |

| Payment Terms: | LC, T/T, PayPal, Western Union, Small-amount payment, Money Gram |

|

Detail Information |

|||

| Installation: | Not Have | Centrifuge Type: | Not Have |

|---|---|---|---|

| Distillation Equipment Type: | Not Have | Extraction Tower Type: | Not Have |

| Pressure: | High Pressure | Condition: | New |

| Equipment Weight: | 108kg | Working Air Pressure: | 0.4-0.6MPa |

| Working Voltage: | AC220V | Flow: | 8000L/H |

| Transport Package: | Wooden Box | Specification: | 790*530*1000mm |

| Trademark: | Datk | Origin: | China |

| After-sales Service: | Life | Warranty: | One Year |

| Type: | Centrifuge | Object: | Cutting Fluid |

| Separation Mode: | Filter Type | Operating Type: | Continuous Type |

| Highlight: | Sludge Cleaning Machine,Extend Cutting Fluid Service Life |

||

Product Description

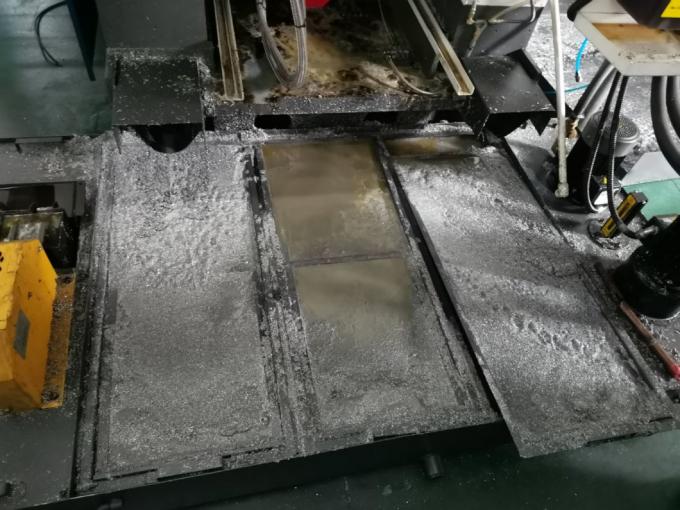

Extend Cutting Fluid Service Life with Sludge Cleaning Machine

At present, for most factories, due to the low content of waste cutting fluid, large amount of wastewater, and difficulty in treatment, some factories mostly adopt direct discharge after dilution, either through protocol dragging or simple treatment, which not only pollutes the environment, wastes resources, but also increases enterprise costs. Therefore, it is particularly important to reduce consumption, energy conservation, and emission reduction by extending the service life of cutting fluid and reducing waste liquid emissions.

Product Introduction

The liquid tank cleaning machine has a wide range of applications, from routine cleaning work to cutting fluid slag removal and fluid replacement, all of which reflect its professional quality. Vacuum cleaning, iron chip suction, slag removal, and other functions can be completed in one go, and can be used in conjunction with a series of equipment such as machine tools. The equipment is designed for dust cleaning, with obvious effects, strong suction, long-lasting non-stop operation, easy cleaning, and no consumables.

Equipment parameters

| Product size | 790 * 530 * 1000mm | Packaging wooden box size | 950 * 650 * 1100mm |

| Equipment weight: about | 108kg | Inlet diameter | 38mm |

| Outlet diameter | 45mm | Inlet diameter | 10mm |

| Working pressure | 0.2-0.5Mpa | Working voltage/power | 220V/3kw |

| Filtering accuracy | 0.75mm (customizable) | Wet extraction flow rate | 7000-8000L/H |

| Maximum dry suction force | -0.04MPa |

Principle of dry suction (electric) function:

The structure of the liquid tank cleaning machine with dry suction function is equipped with multiple detachable heads, filtration systems, vacuum buckets, and vacuum hoses. Turn on the power, the vacuum pump rotates, and the air inside the device is drawn out, generating pressure. Due to the pressure difference, the suction port of the machine body will have airflow flowing into the bucket, while also bringing in garbage. After being filtered by the system, the garbage is left in the vacuum cleaner and the clean liquid is discharged.

Principle of wet suction (pneumatic) function:

The pneumatic chip suction device utilizes the fluidity and pressure difference of high-pressure air to form a negative pressure zone in a specific area. When high-pressure air passes through a nozzle or similar structure, it accelerates the flow and creates a low-pressure zone, thereby attracting surrounding metal debris and cutting fluid into the chip suction pipe.

Want to Know more details about this product