CNC Metal Debris Cleaning Machine,Dual Use Of Dry And Wet

Product Details:

| Place of Origin: | China |

| Brand Name: | Diang Tianke |

Payment & Shipping Terms:

| Price: | Negotiable |

|---|---|

| Delivery Time: | 7-15 workdays |

| Payment Terms: | LC, T/T, PayPal, Western Union, Small-amount payment, Money Gram |

|

Detail Information |

|||

| Installation: | Not Have | Centrifuge Type: | Not Have |

|---|---|---|---|

| Distillation Equipment Type: | Not Have | Extraction Tower Type: | Not Have |

| Pressure: | High Pressure | Condition: | New |

| Equipment Weight: | 108kg | Working Air Pressure: | 0.4-0.6MPa |

| Working Voltage: | AC220V | Flow: | 8000L/H |

| Transport Package: | Wooden Box | Specification: | 790*530*1000mm |

| Trademark: | Datk | Origin: | China |

| After-sales Service: | Life | Warranty: | One Year |

| Type: | Centrifuge | Object: | Cutting Fluid |

| Separation Mode: | Filter Type | Operating Type: | Continuous Type |

| Highlight: | CNC Metal Debris Cleaning Machine |

||

Product Description

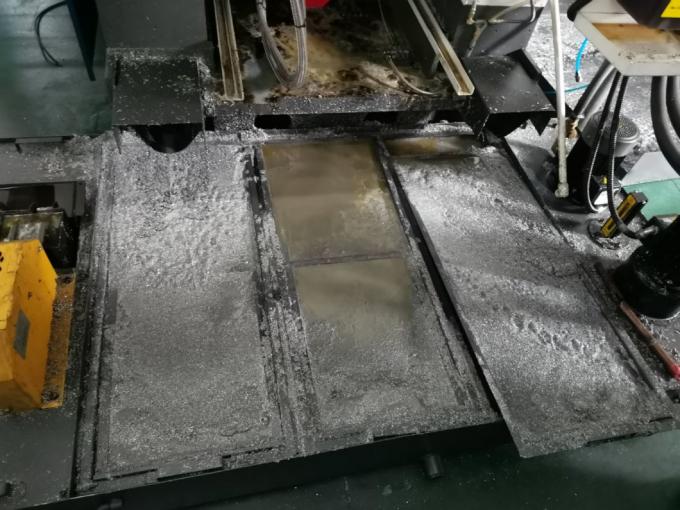

CNC Metal Debris Cleaning Machine,Dual Use Of Dry And Wet

Product Introduction

The liquid tank cleaning machine has a wide range of applications, from routine cleaning work to cutting fluid slag removal and fluid replacement, all of which reflect its professional quality. Vacuum cleaning, iron chip suction, slag removal, and other functions can be completed in one go, and can be used in conjunction with a series of equipment such as machine tools. The equipment is designed for dust cleaning, with obvious effects, strong suction, long-lasting non-stop operation, easy cleaning, and no consumables.

Equipment parameters

| Product size | 790 * 530 * 1000mm | Packaging wooden box size | 950 * 650 * 1100mm |

| Equipment weight: about | 108kg | Inlet diameter | 38mm |

| Outlet diameter | 45mm | Inlet diameter | 10mm |

| Working pressure | 0.2-0.5Mpa | Working voltage/power | 220V/3kw |

| Filtering accuracy | 0.75mm (customizable) | Wet extraction flow rate | 7000-8000L/H |

| Maximum dry suction force | -0.04MPa |

Product advantages:

1. Intelligent structure and fast cleaning speed: The liquid tank cleaning machine has a compact design, high cleaning efficiency, and can quickly complete the pumping and cleaning of a large amount of cutting fluid.

2. Easy to maintain: This device has low maintenance costs and can operate stably for a long time, reducing the maintenance burden on enterprises.

Efficient filtration: Adopting a multi-stage filtration device, it can filter out metal cutting and other impurities in the cutting fluid while pumping, achieving solid-liquid separation.

3. Multifunctional: It can not only be used for purifying cutting fluids and cleaning oil sludge and debris in storage tanks, but also as a cleaning equipment for liquid fluids such as water, ground and machine tool surface debris, oil, etc. splashed out from machining workshops.

4. Energy saving and environmental protection: By purifying and treating emulsions online, recycled water can be recycled and reused, reducing the total amount of emulsion emissions, lowering enterprise emission costs, and saving freshwater resources.

Product Usage:

Suitable for various types of lathes, milling machines, grinders, and saws, it can easily and quickly clean metal debris, sludge, and other impurities in the machine tool water tank, ensuring the full utilization of cutting fluid, simple operation, and easy installation.

About Us

Guangzhou Di'ang Tianke Automation Equipment Co., Ltd. is an enterprise that integrates research and development, production, and sales. The company is based on the current situation of waste liquid pollution in China and conducts in-depth research on suitable equipment and technologies for industrial waste liquid purification and recycling. Our products cover nearly 20 provinces and cities in China, and are exported to Southeast Asia and Europe. The company's main products have passed ISO9001 certification system management and GB/T29490 intellectual property management certification.

After-sale service:

From the date of product sale, our company provides regular quality tracking and follow-up services for the products purchased by users. We provide answers to problems encountered by users in their daily use, solve problems encountered by users during equipment use in real time, communicate and exchange with users about small problems that may occur at each stage of the equipment, prevent equipment failures, detect equipment problems early and eliminate them in a timely manner, to ensure the normal operation of users' equipment.

Want to Know more details about this product