Air Powered And Electric Coolant Tank Cleaner For Large Milling Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | Diang Tianke |

| Certification: | ISO9001 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Delivery Time: | 7-15 workdays |

| Payment Terms: | LC, T/T, PayPal, Western Union, Small-amount payment, Money Gram |

| Supply Ability: | 300/month |

|

Detail Information |

|||

| Working Voltage: | AC220V | Transport Package: | Wooden Box |

|---|---|---|---|

| Warranty: | One Year | Object: | Cutting Fluid |

| Color: | Milky White & Balck | Material: | Stainless Steel |

| Power: | Air Powered And Electric | ||

| Highlight: | Electric Coolant Tank Cleaner,Air Powered Coolant Tank Cleaner,Large Milling Machine CNC Coolant Cleaner |

||

Product Description

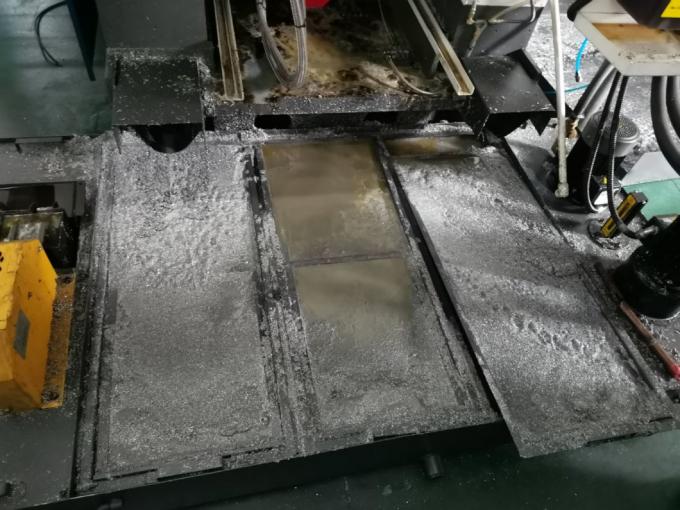

Air Powered And Electric Dual Power Metal Cutting Machine Tool Fluid Tank Cleaning Machine

Large milling machine oil tank cleaning equipment,Machine tool cleaning machine

Guangzhou Di'angtianke Automation Equipment Co., Ltd. is located in Guangzhou and is a research and development manufacturer of one-stop purification production equipment for metal working fluids, as well as a provider of cutting fluid purification solutions. Since its establishment, the company has cooperated with over 1000 enterprises and exported its products to countries such as Japan, the Netherlands, Mexico, Romania, Indonesia, Vietnam, and Malaysia.

| Product size | 790 * 530 * 1000mm | Packaging wooden box size | 950 * 650 * 1100mm |

| Equipment weight: about | 108kg | Inlet diameter | 38mm |

| Outlet diameter | 45mm | Inlet diameter | 10mm |

| Working pressure | 0.2-0.5Mpa | Working voltage/power | 220V/3kw |

| Filtering accuracy | 0.75mm (customizable) | Wet extraction flow rate | 7000-8000L/H |

| Maximum dry suction force | -0.04MPa |

Product Usage:

Suitable for various types of lathes, milling machines, grinding machines, and sawing machines, it can conveniently and quickly clean metal debris, sludge, and other impurities in the machine tool water tank, ensuring full utilization of cutting fluid, simple operation, and convenient installation.

Product features:

1. High flow rate, high suction, fast slag and liquid replacement speed, without affecting production progress;

2. Handheld mode, 360 degree comprehensive cleaning, convenient and fast;

3. High quality stainless steel material, seamless welding technology, with a sheet metal painted appearance, corrosion-resistant and durable;

4. Adhering to the principles of ergonomics, driving is labor-saving and convenient, and easy to grasp by hand;

5. Compressed air drive, no power consumption, zero consumables;

6. Convenient to clean every corner of the workshop, the water tank can be sucked from the ground.

Notes:

1. Timely clean the debris and various vacuum accessories inside the bucket, clean them after each operation, and check for any air leaks;

2. Check if the power cord and plug are damaged. After use, wrap the power coil into a bundle and place it on the top cover of the equipment;

3. If the host heats up, emits a burnt smell, or has abnormal vibration and noise, it should be sent for repair in a timely manner and cannot be used reluctantly;

4. After the water absorption work is completed, check if there are any blockages or debris in the air inlet, otherwise it needs to be cleaned. Check for any damage.